ISO9001 Quality Management System / QMS in AVIATION?

Understanding ISO 9001 in Aviation

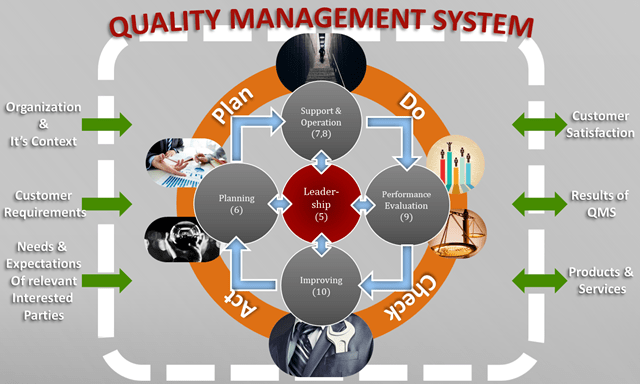

ISO 9001 is an internationally recognized standard for quality management systems (QMS). It provides a framework for organizations to ensure consistent quality in their products and services, meeting customer and regulatory requirements. In the aviation industry, ISO 9001 serves as the foundational quality standard, emphasizing structured, efficient, and safe processes.

The Importance of ISO 9001 in Aviation

The aviation sector demands the highest levels of safety, precision, and reliability. Implementing ISO 9001 in aviation offers several key benefits:

- Consistency: Standardized processes lead to uniformity in production and service delivery.

- Risk Management: Proactive identification and mitigation of potential issues enhance safety and reliability.

- Customer Satisfaction: Delivering high-quality products and services that meet or exceed customer expectations.

ISO 9001:2015 – The Latest Version

The ISO 9001 standard has evolved to address the changing needs of industries. The latest revision, ISO 9001:2015, introduces several significant enhancements:

- Risk-Based Thinking: Encourages organizations to identify and address potential risks and opportunities systematically.

- Leadership Engagement: Emphasizes the active involvement of top management in the QMS to foster a culture of quality.

- Continuous Improvement: Promotes ongoing evaluation and enhancement of processes to improve performance and efficiency.

These features align with the aviation industry’s commitment to safety and operational excellence.

AS9100: The Aerospace Quality Standard

While ISO 9001 provides a robust foundation, the aerospace industry has developed a specialized standard known as AS9100. AS9100 builds upon ISO 9001 by incorporating additional requirements specific to aviation, space, and defense organizations. Key aspects of AS9100 include:

- Enhanced Safety Requirements: Addresses the unique safety considerations inherent in aerospace operations.

- Comprehensive Risk Management: Implements extensive risk assessment and mitigation strategies critical for high-risk environments.

- Product Traceability: Ensures thorough tracking of components and materials to verify origin, quality, and compliance with regulations.

Implementing AS9100 demonstrates an organization’s commitment to meeting the stringent quality and safety standards of the aerospace sector.

Benefits of Implementing ISO 9001 and AS9100 in Aviation

Adopting these standards offers numerous advantages:

- Operational Efficiency: Streamlined processes reduce waste and improve productivity.

- Customer Confidence: Certification signals a dedication to quality, enhancing trust and satisfaction.

- Regulatory Compliance: Ensures adherence to industry regulations and standards.

- Risk Mitigation: Proactive risk management reduces the likelihood of errors and enhances safety.

Steps to Implement ISO 9001 in an Aviation Organization

- Understand Requirements: Familiarize yourself with ISO 9001 and AS9100 standards.

- Assess Current Processes: Identify gaps between existing practices and standard requirements.

- Develop a Quality Manual: Document QMS procedures and policies.

- Train Your Team: Educate staff on quality standards and processes.

- Audit and Improve: Conduct regular audits and implement continuous improvements.

Conclusion

ISO 9001 and AS9100 are integral to maintaining high standards of quality and safety in the aviation industry. By adhering to these frameworks, organizations not only comply with regulatory requirements but also enhance operational efficiency, customer satisfaction, and overall industry reputation.

References & Further Reading:

- www.faa.gov

- www.turcert.com

- www.iata.org

- www.sae.org

- www.icao.int

- web.shgm.gov.tr

- www.skybrary.aero

- ISO 9000 Series Standards

- AS 9100 Series Standards

- EU-OPS 1.035: European Regulation

Special thanks to author of the article Eren BAYCIN.

For more Articles click.