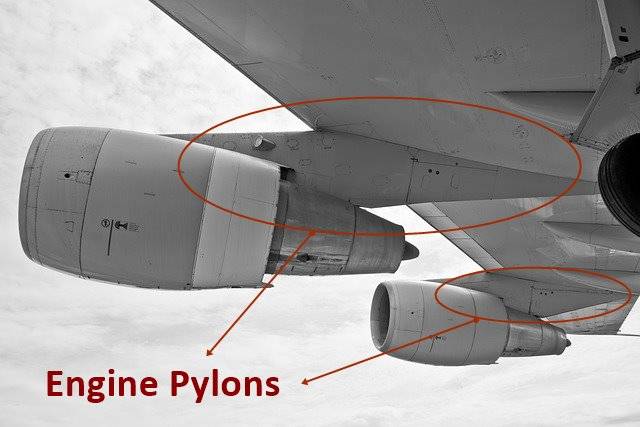

What is an Engine Pylon?

An engine pylon is a structural component that connects an aircraft engine to the wing or fuselage. It provides a mounting point for the engine, as well as a means of transferring the engine’s thrust to the airframe. Pylon designs vary depending on the type of aircraft and engine, but they all share the same basic functions.

The pylon typically consists of a load-bearing structure, a mounting bracket for the engine, and a fairing to protect the engine from the elements. To handle the powerful forces generated by the engine, the engineers designed a load-bearing structure using strong materials like aluminum or steel. The mounting bracket attaches the engine to the pylon and allows it to pivot fore and aft. Lightweight materials like fiberglass or composites make up the fairing, helping to reduce drag and noise.

Engine pylons play an important role in the safety of an aircraft. They help to protect the wing and fuselage from damage in the event of an engine failure or fire. They also help to distribute the weight of the engine evenly across the airframe, which reduces the risk of structural failure.

Here are some of the key functions of an engine pylon:

- Supports the weight of the engine

- Transfers the engine’s thrust to the airframe

- Protects the engine from the elements

- Routes the engine’s fuel, oil, and hydraulic lines

- Provides a mounting point for the engine’s accessories

- Helps to dissipate heat from the engine

- Provides a means of attaching the engine to the wing or fuselage

Engine pylons are an essential component of any aircraft. They help to ensure the safety and performance of the aircraft by providing a secure mounting point for the engine and protecting it from the elements.

Types of Engine Pylons

There are two main types of engine pylons on aircraft: cantilever pylons and pod-and-boom pylons.

Cantilever pylons are the most common type of pylon. They are attached directly to the wing spar, and the engine is supported by the pylon itself. Cantilever pylons are relatively simple and lightweight, and they are well suited for small and medium-sized aircraft.

Pod-and-boom pylons are used on larger aircraft. The engine is mounted on a pod that is suspended from a boom. The boom is attached to the wing spar, and it provides additional support for the engine. Pod-and-boom pylons are more complex and heavier than cantilever pylons, but they offer better performance and safety.

In addition to these two main types, there are also a number of other types of engine pylons, such as:

Folding pylons are used on aircraft that need to be able to fit into tight spaces, such as on aircraft carriers. The pylons fold up against the wing when not in use.

Retractable pylons are used on aircraft that need to reduce drag during cruise flight. The pylons retract into the wing when not in use.

Variable incidence pylons are used on aircraft that need to change the angle of the engine nacelles in flight. This can be done to improve performance or to reduce noise.

The type of engine pylon used on an aircraft depends on a number of factors, such as the size and weight of the aircraft, the type of engine, and the performance requirements.

Conclusion

In conclusion, understanding the role and design of engine pylons is essential for grasping how modern aircraft achieve both safety and efficiency. These components are vital in securely attaching engines to the aircraft, managing weight distribution, and ensuring optimal performance during flight. Whether you’re an aviation enthusiast or a professional, appreciating the complexities of engine pylons underscores the intricate engineering that keeps aircraft flying safely. For a deeper dive into the topic, explore the detailed explanations provided in our full article.

References:

https://aviation.stackexchange.com/questions/79872/what-are-different-components-of-an-engine-pylon

https://arc.aiaa.org/doi/10.2514/1.C035953

Great