Aircraft Tie-Down: Essential Tips and Best Practices

Aircraft tie down is a critical aspect of ground operations that helps ensure the safety and stability of aircraft while they are parked or stored on the ground. In this article, we will discuss what aircraft tie down is, why it is important, and some of the best practices to follow when tying down an aircraft.

What is Aircraft Tie Down?

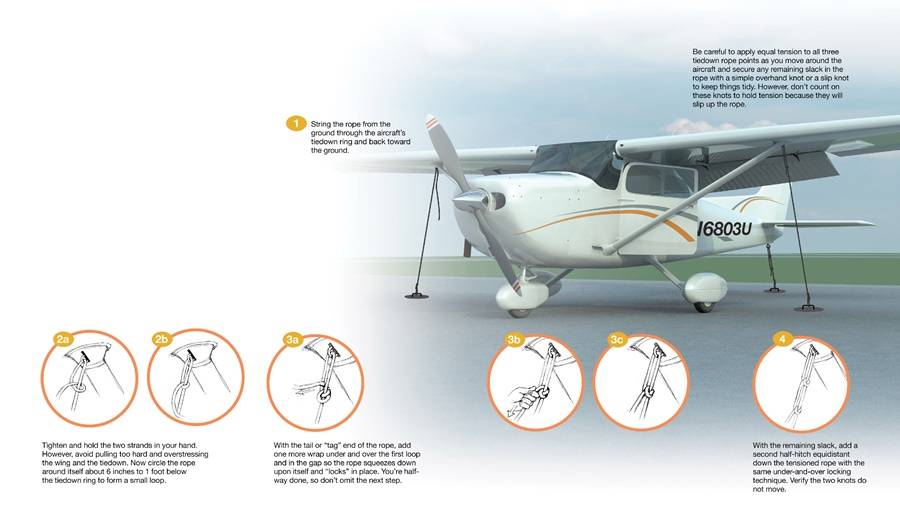

Aircraft tie down refers to the process of securing an aircraft to the ground to prevent it from moving or tipping over due to wind or other environmental factors. Tie down systems typically consist of cables or ropes that are anchored to the ground at fixed points around the aircraft, such as the main landing gear or wing struts.

Why is Aircraft Tie Down Important?

Proper aircraft tie down is critical to ensuring the safety of personnel and equipment on the ground, as well as protecting the aircraft itself from damage. In windy or stormy conditions, an untied aircraft can be easily moved or flipped over, causing serious injury or damage. Additionally, a moving aircraft can damage other aircraft, buildings, or equipment on the ground.

Best Practices for Aircraft Tie Down

When tying down an aircraft, it is important to follow some best practices to ensure that the tie down system is secure and effective. Here are some key guidelines to follow:

- Use approved tie down equipment: Only use equipment that is approved for aircraft tie down, such as aircraft cables, ropes, or straps.

- Choose appropriate tie down points: Tie down the aircraft at designated tie down points, typically located at the main landing gear or wing struts.

- Check for obstacles: Make sure there are no obstacles that could interfere with the tie down system, such as debris, equipment, or other aircraft.

- Use adequate tension: Apply enough tension to the tie down system to keep the aircraft stable, but not so much that it causes damage to the aircraft.

- Check tie down periodically: Regularly check the tie down system to ensure that it remains secure and that there is no damage to the equipment.

Incorrect Tie-Down Points: Avoiding Common Pitfalls

- Challenge: Securing an aircraft at non-designated tie-down points can compromise its stability and cause structural damage. Non-reinforced areas are not built to handle the stress, increasing the risk of failure during high winds or adverse weather.

- Solution: Always consult the aircraft’s manual for the correct tie-down points, such as the main landing gear or wing struts. These areas are specifically reinforced to handle tension. Avoid using random points, as this can lead to costly repairs and unsafe conditions. Regularly inspect and adjust tie-downs, especially before severe weather, to ensure the aircraft is securely anchored.

- Why It Matters: Properly securing your aircraft at the right points not only protects its structure but also ensures safety and compliance with aviation standards. Taking the time to secure tie-downs correctly prevents potential accidents and costly damage.

References:

- Federal Aviation Administration. (2021). AC 20-35C – Aircraft Tie-Downs on Airport Surfaces. Retrieved from https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_20-35C_Chg_1.pdf

- National Transportation Safety Board. (2015). Aircraft Tie-Downs. Retrieved from https://www.ntsb.gov/safety/safety-alerts/Documents/SA_028.pdf

- Aircraft Owners and Pilots Association. (2022). Tie-Downs and Hangars. Retrieved from https://www.aopa.org/training-and-safety/pic-archive/tie-downs-and-hangars

Image source:

https://www.aopa.org/news-and-media/all-news/2022/january/flight-training-magazine/technique-tiedown-tying-tips