Walk Around Check – Outside Check

Aircraft are subjected to a number of control procedures after landing or before taking off from the airport. One of these procedures is Walk around Check / Outside Check. Walk around check is a preflight process.

In this procedure, situations that may prevent the next flight such as whether there is a visible error, defect, wear, fracture, blockage, damage are detected. Usually this check is done visually by a professional walking around the plane. Or, thanks to the developing technology, these controls can be made with the help of specialized drones.

This can be done by the line maintenance personnel or by the pilot of the aircraft.

The purpose of Walk around Check / Outside Check is to determine whether there is a malfunction in the current state of the aircraft that may cause problems to the next flight. A malfunction detected during walk around check is resolved, thus increasing flight safety.

Walk around check is an extremely important procedure for flight safety. For example, a hydraulic leak or physical damage on the landing gear may cause an accident on the runway during the next landing or during take-off. Or, a leak or crack in the aircraft wing may lead to serious incidents during flight.

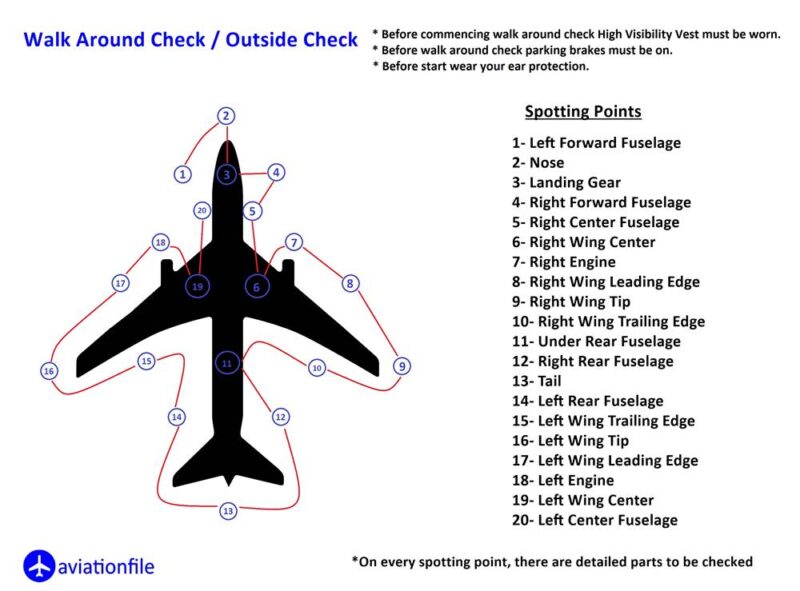

Below you will see a figure that describes the outside check process in general. Note, however, that this process may differ depending on the aircraft type and airline company rules and procedures.

For more articles click.