Value Stream Mapping (VSM) and Its Relevance to Airline Operations

What is Value Stream Mapping (VSM)?

Value Stream Mapping (VSM) is a lean management technique designed to visualize and analyze the entire flow of materials, information, and processes involved in delivering a product or service. By examining both the value-added and non-value-added steps, VSM helps identify inefficiencies, bottlenecks, and sources of waste within a system. The ultimate goal of VSM is to streamline processes, reduce lead times, and improve efficiency, leading to enhanced overall productivity and customer satisfaction. This approach is widely applicable across industries, including airline operations, where complex workflows can benefit from greater coordination and optimization

Application of VSM in Airline Operations

Airline operations involve complex and interconnected activities, such as flight scheduling, ground handling, baggage management, maintenance, catering, and passenger boarding. By using VSM, airlines can analyze and optimize these workflows to minimize delays and maximize operational efficiency.

Key Areas for VSM Implementation in Airlines:

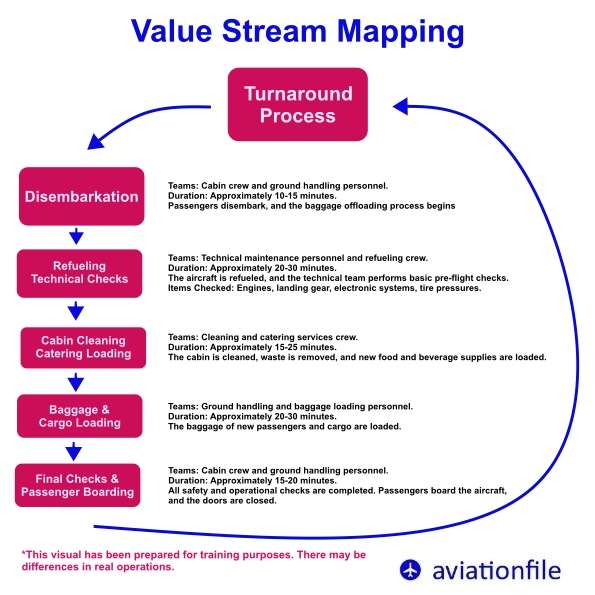

a. Ground Operations (Turnaround Time Optimization):

- Processes involved: Aircraft arrival, gate assignment, refueling, baggage loading/unloading, catering, cleaning, security checks, and passenger boarding.

- Application of VSM: Map the entire aircraft turnaround process, identifying delays, non-synchronized activities, and redundant tasks.

- Improvements: Streamlined coordination between teams, optimized task sequences, and real-time updates can significantly reduce turnaround times.

b. Maintenance and Engineering:

- Processes involved: Preventive maintenance, unscheduled repairs, inspection, part replacements, and documentation.

- Application of VSM: Track the flow of maintenance requests, spare parts, technician assignments, and documentation.

- Improvements: Ensure the availability of critical spare parts, reduce downtime by better scheduling, and improve task completion efficiency.

c. Baggage Handling:

- Processes involved: Baggage check-in, transport to aircraft, loading, unloading, and final delivery.

- Application of VSM: Map the entire journey of baggage to pinpoint delays or mismanagement, such as conveyor jams, labor shortages, or late baggage loading.

- Improvements: Automation of baggage routing, predictive maintenance for conveyors, and synchronized workflows.

d. Passenger Flow Management:

- Processes involved: Ticketing, check-in, security screening, boarding, and in-flight services.

- Application of VSM: Identify bottlenecks at security checkpoints, gate assignments, or during boarding.

- Improvements: Introduce automated kiosks, dynamic gate reassignments, and improved boarding sequences to speed up passenger processing.

e. Flight Operations (Crew and Fleet Scheduling):

- Processes involved: Crew assignments, aircraft rotations, fuel planning, and pre-flight inspections.

- Application of VSM: Map crew scheduling and aircraft availability, highlighting delays caused by miscommunication or unexpected resource unavailability.

- Improvements: Implement dynamic scheduling tools and better communication between teams to prevent flight delays.

Benefits of VSM in Airline Operations:

a. Reduced Turnaround Time:

- By streamlining ground operations, airlines can minimize aircraft idle time and ensure faster readiness for subsequent flights.

b. Improved On-Time Performance:

- Eliminating bottlenecks in both ground and flight processes helps airlines meet departure schedules, reducing delays and cancellations.

c. Enhanced Customer Satisfaction:

- Faster boarding, smooth baggage handling, and reduced delays lead to better passenger experiences and increased loyalty.

d. Cost Savings:

- By reducing fuel wastage, optimizing resource allocation, and preventing unnecessary delays, airlines can achieve significant cost savings.

e. Sustainability Gains:

- Streamlined processes result in less energy consumption, reduced emissions, and lower waste, contributing to environmentally friendly operations.

Example: Ground Operations VSM in Practice

Current State Mapping:

The airline maps processes from aircraft arrival to departure, identifying areas of waste such as excessive waiting times, delays in refueling, and inefficient baggage handling.

Future State Mapping:

Based on insights, the airline redesigns processes to optimize the sequence of tasks, introduce better coordination among ground crews, and implement real-time communication systems. Automated systems for baggage handling and resource allocation ensure minimal disruptions.

Conclusion:

Value Stream Mapping is a vital tool for optimizing airline operations, from ground handling to maintenance and passenger flow. By continuously identifying and eliminating waste, airlines can reduce costs, improve efficiency, and enhance the passenger experience while supporting sustainable aviation goals.

Recommended Article: Airline Quarterly Financial Review