The Hidden Power: Bleed Air in Aviation

When you think about the marvels of modern aviation, the engines, wings, or even the cockpit might come to mind. Yet, hidden within the intricate design of an aircraft is a system that quietly ensures safety, comfort, and efficiency—the bleed air system. This underappreciated component takes compressed air from the engines and turns it into a powerhouse for critical operations, making it an unsung hero in the skies.

What Is Bleed Air?

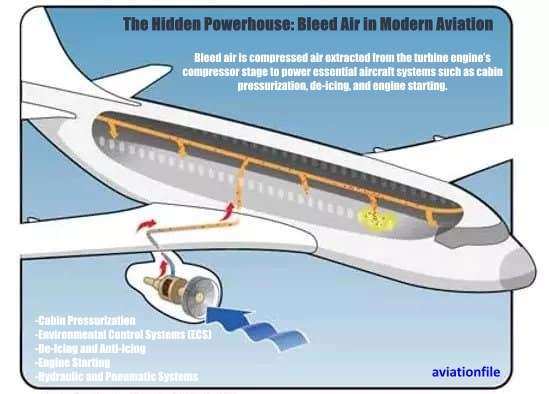

Bleed air is compressed air drawn from the high-pressure compressor section of an aircraft’s turbine engine. This air is extremely hot and under high pressure, making it ideal for various systems on the airplane. However, before use, it is cooled and conditioned to meet operational requirements.

What Is Cross Bleed?

Cross bleed refers to the process of transferring bleed air from one engine to another or to a specific system through an interconnected duct. This is typically used during engine starts in flight or on the ground, particularly when one engine is already running and provides the necessary compressed air to start another. It ensures redundancy and flexibility in engine operations, especially in scenarios where auxiliary power units (APUs) are unavailable or not in use.

How Bleed Air Works

In a typical turbine engine, air enters the intake and is compressed in stages. Some of this compressed air is diverted, or “bleeded,” before it reaches the combustion chamber. This air, known as bleed air, is routed through ducts to power essential systems onboard.

Key Applications of Bleed Air

Bleed air supports multiple vital functions in aircraft operations, including:

- Cabin Pressurization

Maintaining a comfortable cabin environment is one of the primary uses of bleed air. At cruising altitudes, atmospheric pressure drops significantly, making it impossible for passengers to breathe comfortably. Bleed air, when conditioned and regulated, ensures proper cabin pressure for a safe and pleasant flight. - Environmental Control Systems (ECS)

Bleed air powers the air conditioning system to maintain a comfortable cabin temperature. The Environmental Control System uses bleed air to regulate both temperature and humidity, ensuring passenger comfort throughout the flight. - De-Icing and Anti-Icing

Bleed air prevents ice accumulation on critical parts of the aircraft, such as wings and engine inlets. By routing hot bleed air to these surfaces, the system ensures smooth airflow and safe operations even in icy conditions. (Guide to Aircraft De-Icing and Anti-Icing Procedures) - Engine Starting

Bleed air powers pneumatic starters for engines. The compressed air provides the necessary rotational force to initiate the engine start sequence. - Hydraulic and Pneumatic Systems

Certain hydraulic and pneumatic systems onboard rely on bleed air for power. These systems play a vital role in controlling various mechanical components of the aircraft.

What Is a No-Bleed System?

A no-bleed system is an advanced technology used in modern aircraft, such as the Boeing 787, which eliminates the need for traditional bleed air extraction from engines. Instead, it relies on electrically powered systems to perform functions like cabin pressurization, air conditioning, and de-icing. By reducing the dependency on engine power for these operations, no-bleed systems significantly enhance fuel efficiency, lower maintenance costs, and improve overall system reliability. This innovative approach reflects the industry’s shift toward greener and more efficient aviation technologies.

Safety Considerations

While bleed air is indispensable, its operation involves strict safety measures:

- Air Quality Control: The air must be properly filtered to avoid contamination, ensuring passenger health.

- Temperature Management: Bleed air is extremely hot when extracted. Advanced cooling systems are employed to reduce its temperature before use.

- Leak Prevention: Regular maintenance checks ensure the integrity of the bleed air ducts and valves to prevent leaks.

Operational Considerations on the Apron

From an air traffic controller’s perspective, the use of bleed air systems on the apron comes with specific regulations to ensure safety and efficiency. One such regulation mandates that bleed air operations, such as engine starts or air supply for pneumatic systems, must be conducted away from parking positions (example: After pushback, on the apron centerline). This precaution minimizes risks associated with high-temperature exhaust or potential air contamination near other parked aircraft, ground personnel, and equipment. Air traffic controllers coordinate these operations to designated areas on the apron, ensuring compliance with airport safety protocols and reducing hazards during ground operations.

Challenges and Alternatives

Bleed air systems are efficient but not without drawbacks. They consume engine power, reducing fuel efficiency. To address this, many modern aircraft, such as the Boeing 787, use electrically powered systems instead of traditional bleed air systems. These bleed-less designs improve fuel economy and simplify maintenance.

Final Thoughts

Bleed air is a cornerstone of modern aviation, powering critical systems that enhance safety, efficiency, and passenger comfort. As technology evolves, engineers continue to innovate, improving the efficiency and reliability of these systems.

Understanding the role of bleed air in airplane operations provides valuable insight into the complexity and ingenuity of modern aircraft. Whether you are an aviation professional or an enthusiast, appreciating the importance of this system underscores the marvel of flight.

Further Reading:

- Aircraft Clean Air Requirements Using Bleed Air Systems – scientific research page

- Reliability analysis of bleed air anti-icing system based on subset simulation method – ScienceDirect link

- 787 Dreamliner-Boeing Official website