Taking Flight on Efficiency: A Deep Dive into Tech Reducing Fuel Burn

The environmental impact of aviation is a major concern, but the industry is taking flight with innovative solutions. Fuel efficiency is a top priority, and advancements in materials, engines, and aerodynamics are making significant strides. Let’s delve deeper into these technological marvels:

1. Shedding Weight: The Power of Advanced Materials

Modern aircraft are on a diet thanks to revolutionary materials. Carbon fiber composites (CFCs) steal the show. These incredibly strong yet lightweight materials allow for thinner and lighter wings and fuselages. Compared to traditional aluminum, CFCs can shave off significant weight, leading to a direct reduction in fuel consumption. Imagine a plane carrying hundreds of passengers – every pound saved translates to less fuel needed to propel it through the air.

Beyond CFCs, other lightweight materials are making their mark. Titanium alloys offer a strong-to-weight ratio, ideal for landing gear and engine components. Additionally, advanced polymers are finding applications in interior components and even some structural elements, further reducing overall weight.

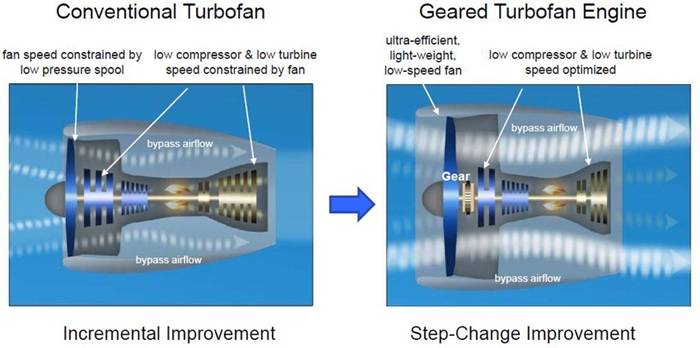

2. Engine Revolutions: Geared Turbofans and Beyond

Aircraft engine design is no longer stuck in high gear. Traditional turbofan engines are constantly being improved. Geared turbofans (GTFs) are a game-changer. Unlike their conventional counterparts, GTFs feature a separate gear system that optimizes fan speed for different flight phases. During takeoff and climb, the fan spins at a higher speed, generating more thrust. At cruising altitude, the gears lower the fan speed, reducing drag and improving fuel efficiency by up to 15-20% compared to older engines.

The future holds even more promise. Open rotor engines, still under development, possess a revolutionary design with exposed fan blades. This design promises significant fuel savings (potentially up to 30%) by maximizing engine efficiency. However, challenges like noise reduction need to be addressed before widespread adoption.

3. Aerodynamics: The Art of Slicing Through Air with Minimal Resistance

Airplanes aren’t just metal tubes with wings anymore. They’re constantly being sculpted for optimal airflow, a science known as aerodynamics. Here’s how:

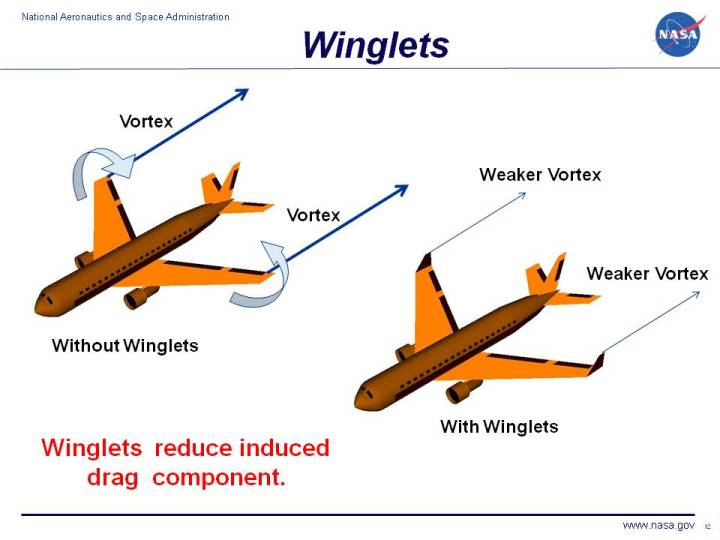

- Wing Design: Modern wings are not just flat surfaces for generating lift. Winglets, those upward extensions at the wingtips, help reduce drag by minimizing wingtip vortices, swirling air currents that create drag. Additionally, advanced wing designs with optimized curvature and sweep angles contribute to smoother airflow, reducing overall drag.

- Smoother Fuselages: Gone are the days of boxy airplanes. Modern aircraft boast sleek and streamlined fuselages that minimize resistance as they cut through the air. This seemingly minor change can significantly improve fuel efficiency, especially on long-haul flights.

- Active Flow Control: This cutting-edge technology uses tiny jets of air or even plasma to manipulate airflow over the wings and other surfaces. This allows for real-time adjustments to optimize lift and reduce drag, further enhancing fuel efficiency.

The Takeaway: A Greener Future for Flight

By combining these advancements, the aviation industry is fostering a more sustainable future. Lighter planes, more efficient engines, and smarter aerodynamics contribute to a significant reduction in fuel consumption and CO2 emissions. This not only benefits the environment but also translates to lower operating costs for airlines, ultimately leading to more affordable and eco-friendly air travel for passengers.