Runway Friction – Braking Action

What is runway surface friction? What are the braking values? How and with which devices are braking measurements made? What are the factors affecting runway surface friction? Yes, we will examine the answers to these questions in this article.

The movements of the planes on the runway are mainly due to the friction force that occurs when the landing gear and the runway come into contact on the runway. Let’s think of ourselves, we find it very difficult to walk on a slippery piece of ice in winter. And most of the force we put into it is useless since there is no friction. Or when you come running over an ice floe and let yourself go, you slide a long distance and have trouble stopping, right? Or, on the contrary, on a dry and smooth asphalt ground, your feet do not slip and you can do the movement you want without difficulty. The extreme examples here are of great help in understanding the surfaces of runways at airports.

Friction effects of runway surfaces are also very valuable for airplanes. It affects every movement the plane makes on the runway. In summary, we can say that the runway surface friction is the counter force that occurs when the aircraft come into contact with the runway surface and move in one direction. They become very important especially during the landing of the aircraft and in the rejected take-off situation.

For these reasons, runway braking measurements are made in airport operations when necessary. And the values obtained as a result of this measurement are transmitted to the pilots of the relevant aircraft. At the same time, braking measurement values can also be added to ATIS publications, thus enabling pilots to be aware of up to date runway conditions.

What are the Factors Affecting the Runway Surface Braking Values?

The most important factor affecting runway surface braking values is meteorology, besides, a FOD or a leak on the runway also affects braking values. If we look at the meteorological conditions. Conditions such as rain, dew, snow, mud reduce the runway surface braking values. Especially when the rain first starts, the period when it mixes with the fine dust layer on the runway can seriously affect the braking values and is dangerous. In addition, puddles or muddy areas on the runway surface also affects braking. Or icing on the runway surface also reduces friction. Meteorological conditions directly affect the runway surface, so we can add many more conditions as examples.

We can say that another factor affecting braking and runway surface friction is the fluids caused by leaks on the runway. For example, a hydraulic leakage problem experienced by a landing airplane can make the runway surface slippery and reduce friction. In such cases, the operation may be suspended for a while to clear the runway. And if the cleaning process is going to take a long time, the runway may be notamed. If there is more than one runway at the airport, the operation can be continued by using other runways.

Tire Marks on Runway Surface

We can say that another factor that affects braking is the tire marks on the runway surface. Although it does not seem like a very important factor at first, a significant amount of tire tracks accumulate on the surface of the runways at airports that are with heavy landing and departure traffic. Therefore, these tire tracks form a layer between the surface of the runway and the landing gears of the aircraft, disrupting the natural surface structure of the runway. Therefore, tire tracks are cleaned periodically by related professionals. This is a time-consuming process, so it is usually done during hours of low flight traffic, or during this process the runway is notamed and maybe closed for use.

What are the Runway Braking Values?

Runway braking measurements are made by dividing the runway into three sections, that is, the first 1/3 section on the landing side, the second is the 1/3 section in the middle and the 1/3 section at the end of the runway. In this way, pilots know what they will encounter.

Runway braking measurements are made with skiddometer devices. These devices have different types and models. Some are systems that are installed in the back of a vehicle and operate this way. You can see examples below.

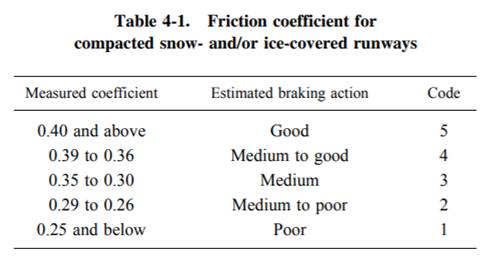

Finally, let’s look at how the braking values are expressed. The Coefficient values obtained during the measurements are used to classify the results and for example, if this value is 0.25 or less in ICAO standards, a code of 1 is given and it is called poor braking. You can see the detailed classification in the Sample Table below.

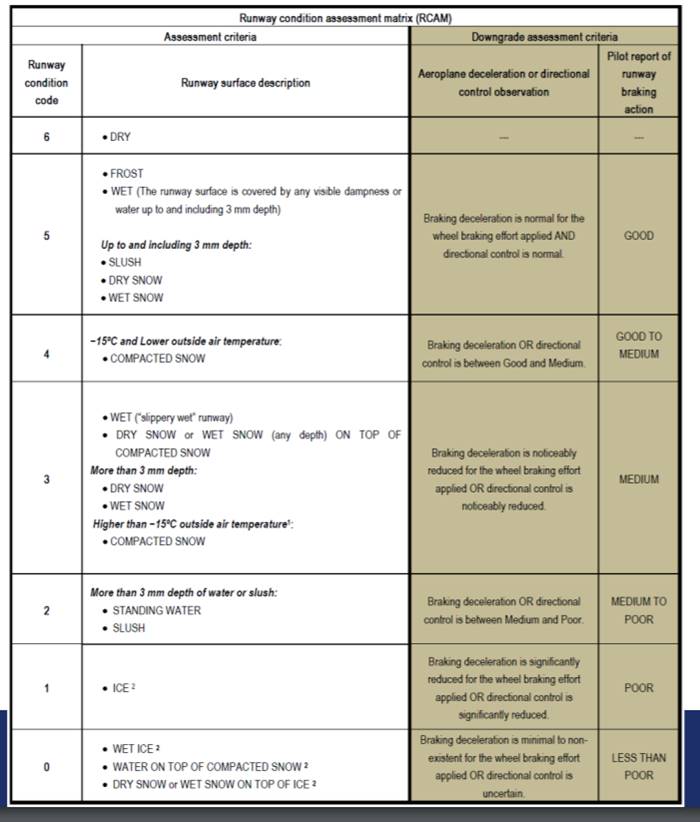

You can see the matrix of “FAA Runway Condition Assesment” below.

For ICAO documentation click.

For FAA RUNWAY CONDITION ASSESSMENT MATRIX (RCAM) click.