How do PAPI Lights Work?

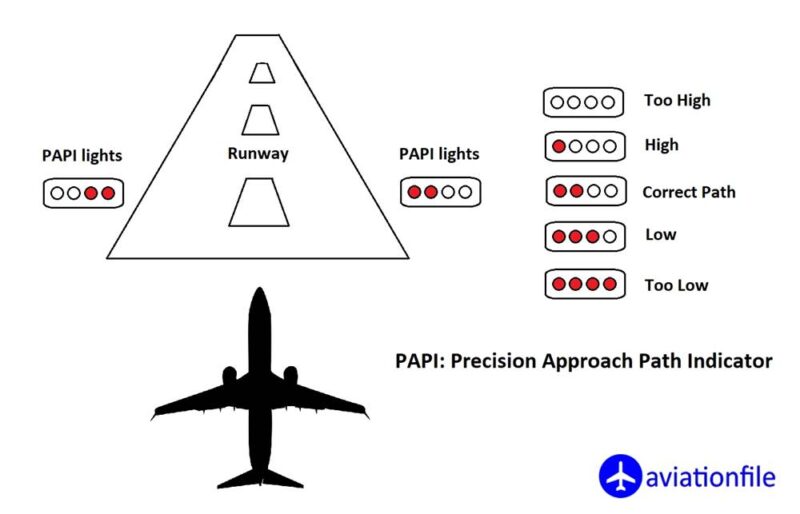

PAPI (Precision Approach Path Indicator) is one of the main Visual Aids established right and left sides of runway (sometimes PAPI can be just in the left or just in the right side of runway but usually on the left because the captain pilot sits also on the left side in the cockpit). PAPI lights generally consist of four equivalent round shaped light units to indicate the vertical position of the approaching aircraft.

The international standard of PAPI is published by ICAO (International Civil Aviation Organisation) Annex 14 Volume 1, Chapter 5.

The earlier glideslope indication system VASI (Visual Approach Slope Indicator) is now inadequate and was deleted by ICAO in 1995. The main difference between VASI and PAPI is VASI only provides guidance down to heights of 60 metres (200 ft) whereas PAPI provides guidance down to flare initiation (typically 15 metres, or 50 ft).

Meaning:

PAPI lights indicate the vertical position of the aircraft according to the optimum approach slope. In detail there are four lights on a PAPI and if the approaching traffic is on the optimum position PAPI lights are two red and two right.

(Red lights on the module always burn near to the runway)

Let’s continue. If the approaching aircraft is flying above the optimum height than white lights increase and there are three white lights and one red light burn on PAPI. If the aircraft is too high than the optimum then it turns to four white lights.

On the other side, if the traffic is lower than the optimum height, red lights start to increase. As expected if the traffic lower than the optimum then three red light burn on PAPI (Red lights are always near to the runway) and if the traffic is too low than the optimum then PAPI turns to four red lights.

(Relatively being lower than the optimum level (height) is more dangerous for an aircraft. So the colour red symbolizes danger as we all know).

Who Operates PAPI Lights?

PAPI is normally operated by Air Traffic Controllers (ATCs). If ATC services are not normally provided at an aerodrome, along with other airport lights they may be activated by the Pilot by keying the aircraft microphone with the aircraft’s communication radio tuned to the CTAF or dedicated pilot controlled lighting (PCL) frequency.

Maintenance and Calibration of PAPI Lights

Regular maintenance and calibration of PAPI lights are essential to ensure accuracy and reliability. Proper upkeep helps PAPI systems deliver precise visual cues for pilots, maintaining safety standards on runways. Here’s a breakdown of key maintenance practices:

- Routine Inspections

Conduct regular inspections to identify any damage or issues. Inspect lenses, bulbs, and housings for cracks, dirt, or debris. Clear lenses maintain the visibility of red and white light signals, essential for accurate pilot guidance. - Cleaning Light Units

Clean the lenses and exterior surfaces of PAPI light units frequently. Dust, watermarks, or grime can obstruct light signals, affecting the visibility of colors from the cockpit. - Bulb Replacement

Replace bulbs as needed to ensure consistent light intensity. Low-intensity or flickering lights can confuse pilots and reduce the effectiveness of the PAPI system. Check with manufacturers for bulb lifespan recommendations. - Calibration Process

Calibrate PAPI lights at least once every six months to ensure accuracy. Calibration adjusts the lights to project the correct angles for approach guidance. Technicians use specific tools to measure the angle of each light in the system. - Angle Verification

Verify the angles of each light unit to maintain the correct red-to-white light ratio. This step ensures that the lights indicate the right glide path for approaching aircraft. Adjustments may be necessary due to environmental factors or ground shifts. - Electrical Component Checks

Inspect electrical components, including wiring and power sources. Secure connections prevent interruptions in light function, especially critical during night or low-visibility conditions. - Weather Impact Assessments

Assess the impact of environmental factors, like heavy rains or snow. Ensure that water drainage systems around PAPI lights function properly. Excess moisture can damage the lights and reduce their visibility. - Documentation of Maintenance

Record each maintenance and calibration activity. Documentation helps track the condition of each unit and schedule future inspections. Detailed logs also assist in regulatory compliance and auditing.

Consistent maintenance and calibration of PAPI lights enhance their reliability. These steps ensure that pilots receive accurate guidance on their approach, supporting safer landings at airports worldwide.

References:

- FAA Advisory Circular 150/5345-42: Precision Approach Path Indicator (PAPI) Systems

- Pilot’s Handbook of Aeronautical Knowledge (PHAK): Chapter 11: Airport Lighting

- Wikipedia: Precision Approach Path Indicator (PAPI)

- Skybrary: PAPI (Precision Approach Path Indicator)

- Boldmethod: How PAPI Lights Work

For a detailed video click

For more articles click