Harnessing Digital Twin Technology for Transforming Aviation: Enhancing Safety, Efficiency, and Innovation

Introduction to Digital Twin Technology

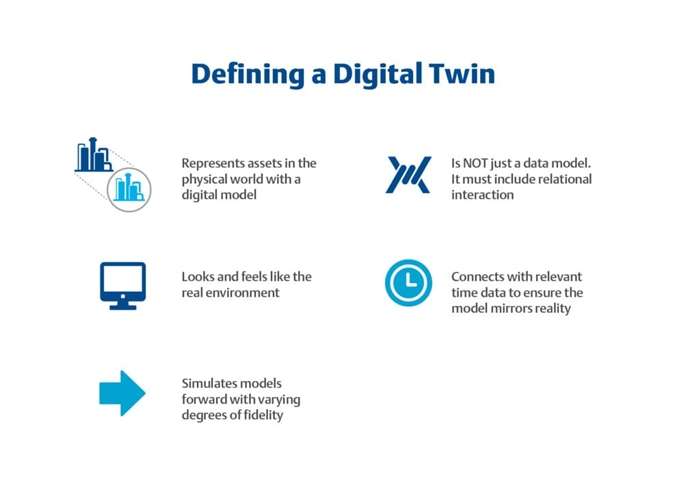

Definition and Core Concepts

Digital twin technology refers to the creation of a virtual replica of physical assets, processes, and systems. This digital counterpart enables real-time monitoring, simulation, and analysis of its real-world twin. Originating from the fields of engineering and manufacturing, digital twins have evolved with advancements in IoT (Internet of Things), data analytics, and AI, offering unprecedented capabilities to various industries, including aviation.

Historical Development and Technological Advancements

The concept of digital twins was first introduced by Dr. Michael Grieves in 2002, primarily for product lifecycle management. Over the years, advancements in sensor technology, big data, and machine learning have significantly enhanced the functionality and applicability of digital twins. Today, they are integral to predictive maintenance, operational efficiency, and innovative design solutions in aviation.

Digital Twin Applications in Aviation

Aircraft Design and Manufacturing

Streamlining Design Processes

Digital twins streamline aircraft design by providing detailed simulations and analyses. Engineers can test different materials, aerodynamics, and structural configurations in a virtual environment, reducing the need for physical prototypes. This accelerates the design process and ensures higher precision and efficiency.

Enhancing Precision in Manufacturing

In manufacturing, digital twins enhance precision by monitoring and optimizing production processes in real-time. They ensure that components are manufactured to exact specifications, reducing errors and waste. This leads to higher quality aircraft with fewer defects and lower production costs.

Predictive Maintenance

Real-Time Monitoring of Aircraft Components

Digital twins enable real-time monitoring of aircraft components, continuously collecting and analyzing data from sensors embedded in various parts of the aircraft. This allows for early detection of wear and tear, enabling timely maintenance interventions.

Reducing Downtime and Maintenance Costs

By predicting potential failures before they occur, digital twins help airlines reduce unplanned downtime and maintenance costs. Predictive maintenance schedules are optimized based on actual usage and condition, rather than fixed intervals, leading to more efficient and cost-effective maintenance practices.

Flight Operations and Performance Optimization

Improving Fuel Efficiency

Digital twins can simulate and analyze various flight scenarios to optimize fuel efficiency. By assessing different flight paths, speeds, and altitudes, they help pilots and airlines select the most fuel-efficient routes, significantly reducing fuel consumption and operating costs.

Enhancing Flight Safety through Predictive Analytics

Using predictive analytics, digital twins can enhance flight safety by identifying potential risks and providing actionable insights. They can simulate emergency scenarios and guide pilots through best practices, improving their preparedness and response capabilities.

Case Studies and Real-World Examples

Leading Airlines and Aerospace Companies Utilizing Digital Twins

Several leading airlines and aerospace companies are already leveraging digital twin technology. For instance, GE Aviation uses digital twins to monitor and optimize engine performance, resulting in improved reliability and reduced maintenance costs. Similarly, Airbus employs digital twins in their manufacturing processes to enhance precision and efficiency.

Success Stories and Measurable Benefits

Rolls-Royce has reported significant improvements in engine maintenance and performance optimization through digital twin technology. By using digital twins for predictive maintenance, they have reduced engine downtime by 30% and cut maintenance costs by 15%. These measurable benefits highlight the transformative potential of digital twins in aviation.

Challenges and Limitations

Technical and Implementation Barriers

Despite its advantages, implementing digital twin technology in aviation comes with technical challenges. Integrating digital twins with existing systems requires significant investment in infrastructure, including sensors, data storage, and processing capabilities. Additionally, ensuring the accuracy and reliability of the digital twin models is crucial for their effectiveness.

Data Security and Privacy Concerns

The extensive use of data in digital twin technology raises significant security and privacy concerns. Protecting sensitive information from cyber threats is paramount, and companies must implement robust cybersecurity measures to safeguard data integrity and confidentiality.

Integration with Existing Aviation Systems

Integrating digital twins with existing aviation systems and processes can be complex. Ensuring compatibility and seamless communication between different systems requires meticulous planning and coordination among various stakeholders.

Future Prospects and Innovations

Potential Advancements in Digital Twin Technology

Future advancements in digital twin technology will likely include enhanced AI and machine learning algorithms, more sophisticated simulations, and greater integration with other emerging technologies like blockchain and augmented reality. These innovations will further enhance the capabilities and applications of digital twins in aviation.

Long-Term Impact on the Aviation Industry

In the long term, digital twin technology is expected to revolutionize the aviation industry. By enabling more efficient and safer operations, it will drive significant cost savings and operational improvements. Additionally, the continuous evolution of digital twins will foster innovation in aircraft design, manufacturing, and maintenance.

Collaboration Between Aviation Stakeholders and Tech Companies

Collaboration between aviation stakeholders and technology companies is essential for the successful implementation and advancement of digital twin technology. Joint efforts in research, development, and standardization will ensure that the benefits of digital twins are maximized across the industry.

Conclusion

Digital twin technology holds transformative potential for the aviation industry. By enhancing safety, improving efficiency, and driving innovation, digital twins are set to revolutionize aircraft design, manufacturing, maintenance, and operations. The aviation industry must embrace this technology to stay competitive and meet the evolving demands of safety, efficiency, and sustainability.

References and Further Reading Links

- https://www.lhsystems.com/blog-entry/transformative-power-digital-twins-aviation

- https://www.rolls-royce.com/media/our-stories/discover/2019/how-digital-twin-technology-can-enhance-aviation.aspx

- https://www.sciencedirect.com/science/article/pii/S2542660523003141

- https://twinsights.co/resources/blogs/digital-twins-fly-high-in-the-aviation-industry/

- https://www.chemengonline.com/understanding-the-digital-twin/