Guide to Aircraft De-Icing and Anti-Icing Procedures

Aircraft operate in diverse atmospheric conditions, often encountering weather phenomena like rain, snow, fog, and lightning. Even when ambient temperatures are not extremely low, specific atmospheric conditions can lead to ice formation on aircraft surfaces. To ensure flight safety under such circumstances, airlines implement de-icing and anti-icing procedures.

De-Icing vs. Anti-Icing

- De-Icing: This procedure involves removing existing ice, snow, or frost from the aircraft’s exterior surfaces. Typically, heated de-icing fluids are sprayed under pressure to melt and eliminate these contaminants, restoring the aircraft’s aerodynamic properties.

- Anti-Icing: This preventive measure aims to inhibit the formation of ice on aircraft surfaces. Anti-icing fluids, which are more viscous than de-icing fluids, are applied to create a protective layer that prevents ice accumulation during operations.

Application Conditions

Anti-icing and de-icing procedures are essential during active frost conditions, such as temperatures around 0°C or during precipitation events like snow, slush, or freezing fog. These conditions can adversely affect an aircraft’s aerodynamic performance, making these treatments crucial for safe operations.

Cold Soak Effect

A phenomenon known as the “Cold Soak Effect” can lead to transparent ice formation on aircraft wings. This occurs when aircraft descend from high altitudes or refuel with cold fuel, causing wing surfaces to cool significantly. Even in ambient temperatures between 0°C and +15°C, moisture can freeze upon contact with these cold surfaces, necessitating de-icing procedures.

Decision Authority

The captain holds the ultimate responsibility for deciding whether de-icing or anti-icing is necessary. Pilots assess weather conditions and the aircraft’s status to determine the need for these procedures, ensuring safety without unnecessary delays.

Anti-Icing Fluids and Holdover Time

- Fluid Characteristics: Anti-icing fluids are typically green and possess higher viscosity than de-icing fluids. This viscosity enables them to adhere to aircraft surfaces, preventing the accumulation of snow or slush during taxiing.

- Holdover Time (HOT): HOT refers to the duration during which the anti-icing fluid remains effective. Factors such as fluid type, weather conditions, and precipitation intensity influence HOT. Aviation authorities like the FAA and Transport Canada publish annual HOT guidelines to assist flight crews in making informed decisions.

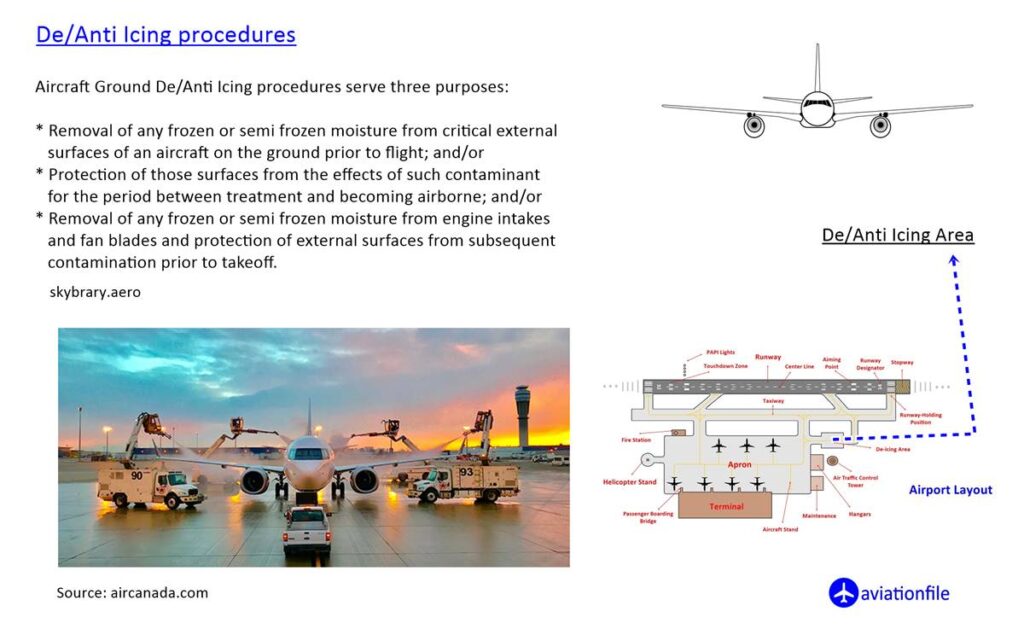

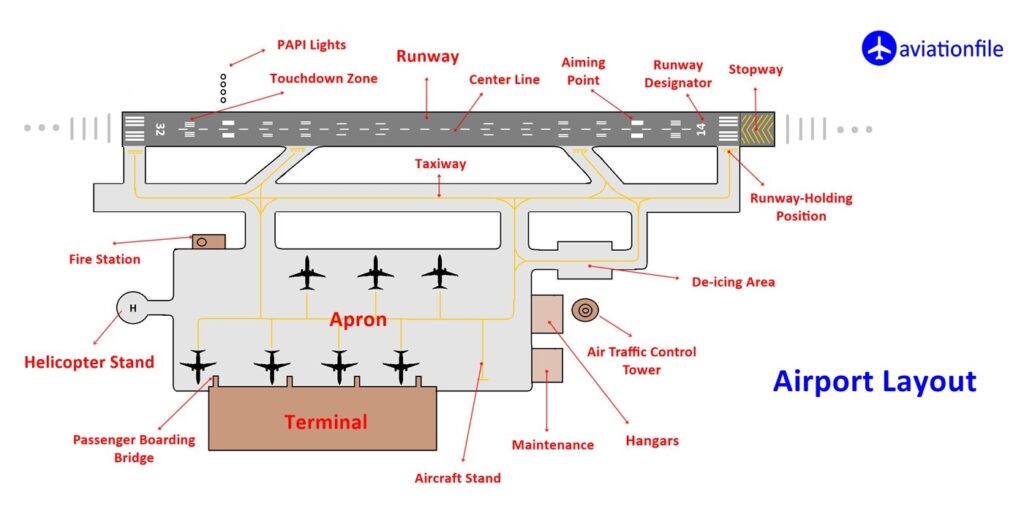

De-Icing Locations at Airports

De-icing operations are conducted in designated areas at airports, often near runway thresholds, to minimize taxi time post-treatment. This proximity ensures that aircraft can take off before the anti-icing fluid’s effectiveness diminishes. Environmental considerations play a role in determining de-icing locations, as some airports restrict these operations at terminal gates to prevent environmental contamination.

Environmental Considerations

De-icing fluids, particularly those based on glycols, can have environmental impacts. These substances are toxic to humans and other mammals and can damage ecosystems around airports. Their use may lead to changes in nearby aquatic habitats, adversely affecting fish and other wildlife. Vikipedi

Conclusion

De-icing and anti-icing procedures are vital for maintaining flight safety in adverse weather conditions. By effectively removing and preventing ice accumulation, these operations ensure that aircraft maintain optimal aerodynamic performance, thereby safeguarding passengers and crew.

For more artciles click.